Inventory count procedure

Lot size-based discounts are justified to achieve coordination for commodity products. Lot-sized discounts are based on quantity purchased per lot, not the rate of purchase.

This is usually the best option for larger companies who need consistent reports. A company may have employees perform daily physical counts of certain warehouse locations or rank products that need the most attention. Cycle count programs are a great way to ensure you maintain inventory accuracy throughout the year, and many companies employee a combination of cycle counting and 100 percent physical inventories. For instance, they may cycle count their key products (or “A” products) throughout the year and count all products during their 100% physical inventory. Use this inventory cycle count Excel template to track ongoing cycle counts.

If the outside auditors feel they can rely on these inventory records, they may scale back their audit procedures, which in turn reduces the audit fees they charge to the company. Also, there would no longer be a need to pay employees overtime to count inventory, or to close down the production area while physical counts are conducted. Effective Inventory Management Inc. described the cycle method as segmenting a warehouse and physically inventorying a part of it every day.

How often should you cycle count inventory?

A cycle count is an inventory auditing procedure, which falls under inventory management, where a small subset of inventory, in a specific location, is counted on a specified day.

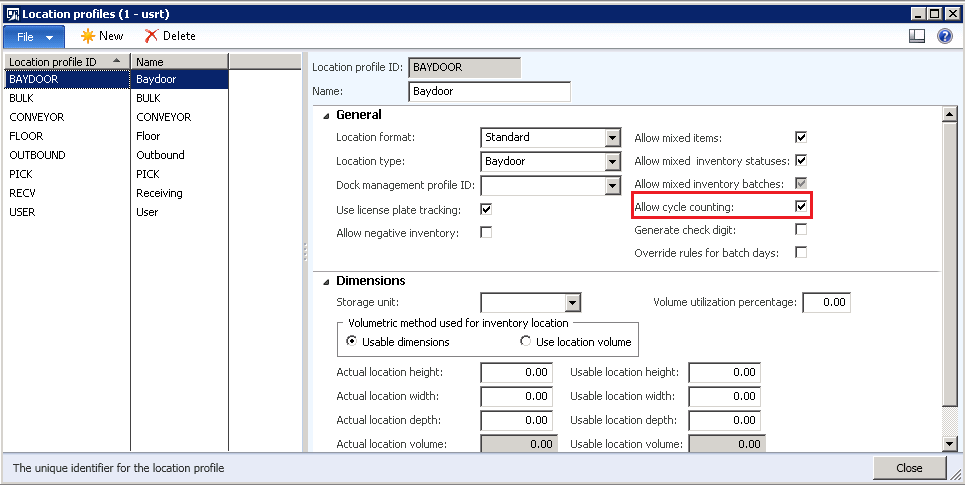

Multiple locations per item, work in process, and lag in paperwork processing can each contribute to errors. This problem can be mitigated with correct cycle count procedures that specify not only the part number to be counted but also the location it should be in. Cycle counting is only effective in companies with a well-defined inventory control procedure and a high degree of inventory accuracy. To conduct efficient and accurate cycle counts, many organizations use some form of software to implement an inventory control system, which is part of a warehouse management system. These systems may include mobile computers with integrated barcode scanners that allow the operator to automatically identify items, and enter inventory counts via keypad.

Cycle counting by usage only

The eventual result should be detailed procedures and training that yield very low transaction error rates and high levels of inventory record accuracy. According to this sample, all company inventory should be cycle counted on a periodic basis in order to substantiate current inventory balances. Cycle counts should be performed (daily/monthly/quarterly) using a random selection process. In addition to routine daily cycle counting, there may be “special” audit counts of inventory. Cycle counting that begins from one end of the store to the other, based on surface area.

So, you can see that if your inventory count is incorrect, your COGS won’t be accurate either! In some businesses, COGS accounts for one third of the total business expenses, so it is important to have a good handle on these costs. In addition, monitoring your COGS is a good way to identify operational problems within your business.

The terms stock and inventory are used interchangeably, but in actuality, the terms have two separate meanings. Although the difference is rather subtle, from an accounting standpoint, it’s very important to your small business. In order to give an accurate accounting of items the business owns, learn the difference between the two terms and use them correctly. Counting your inventory correctly is critical because it’s used to calculate one of the most important financial indicators for some types of business – Cost of Goods Sold (COGS). Specifically, the calculation of COGS is beginning inventory (what you already had) plus purchases during the period (what you bought new and added to the beginning inventory), less ending inventory (what you have left).

As a business sells its cycle stock inventory and replenishes it, its cash flow accounts for the income it receives and the payments it makes. Cycle stock inventory is also part of a company’s total assets on its balance sheet. Physical Inventory or Cycle counting is used to streamline the inventory of the items within warehouse and the inventory shown in the sytem ( that is to tally the actual inventory and the on hand showing in the system).

Without Inventory Accuracy

This method may be biased against counting higher value inventory or require additional counting to satisfy accounting requirements. Cycle counting, an alternative to physical inventory, may be less disruptive. A cycle count is an auditing procedure whereby a small subset of inventory, usually in a specific location, is counted at a specific day or time. The goal is to move through all inventory on a regular basis. Cycle counting yields more accurate inventory results.

How do you calculate inventory cycle counts?

Cycle count programs sometimes target counting all SKUs over a given period (i.e. a fiscal year). But more often, cycle count programs target counting the “A” items over that period. “A” items typically follow the 80/20 rule, as in they are the top 20 percent of your SKUs that represent 80% of your inventory value.

Choose your method—whether you use a control group, a random sample or ABC analysis—before you begin the practice of cycle counting. If you’re ready to automate cycle counts, check out Systum’s inventory and order management software. Many companies are aware of how important it is too keep track of their inventory.

- Although some say that cycle counting should only be performed in facilities with a high degree of inventory accuracy (greater than 95%), cycle counting is one means of achieving and sustaining high degrees of accuracy.

- A cycle count is an inventory auditing procedure, which falls under inventory management, where a small subset of inventory, in a specific location, is counted on a specified day.

- Cycle counts contrast with traditional physical inventory in that a full physical inventory may stop operation at a facility while all items are counted at one time.

Combing over each rack or shelf, that is assigned per counter. This method requires planning, in which a map of the store is required and counting forms for the recording of stock information that will then need updating to the inventory management system. Cycle counting by usage states that items more frequently accessed should be counted more often, irrespective of value. Every time an employee adds or removes an item, there is a risk of introducing inventory variance. Logical inventory zones can be set up to distinguish items depending on how frequently they are touched.

Determining selection method and count frequency

Many companies perform “mini” physical inventories and call it cycle counts. Instead of using random or system generated part numbers at specific locations to count, they selectively choose specific locations and count everything in those locations. As part of their procedures they rotate throughout the plant with the intention of counting every location a minimum of once each year. This is an effective alternative to true cycle counting where a company may not have the sophistication to utilize cycle counting software. Lessons from Discounting Schemes Lot size-based discounts increase lot size and cycle inventory in the supply chain.

Businesses may use several different tactics to minimize the disruption caused by physical inventory. Cycle stock inventory serves an important function in a company’s accounting.

The software transmits data to a database on a host system which can generate inventory reports. Physical inventory is a process where a business physically counts its entire inventory. A physical inventory may be mandated by financial accounting rules or the tax regulations to place an accurate value on the inventory, or the business may need to count inventory so component parts or raw materials can be restocked.

Volume-based discounts are based on the rate of purchase or volume purchased on average per year or month. Volume-based discounts are compatible with small lots that reduce cycle inventory. Lot size-based discounts make sense only when the manufacturer incurs a very high fixed cost per order. The items selected for cycle counts can be defined based on many sort criteria, such as most used or highest cost.

Although some say that cycle counting should only be performed in facilities with a high degree of inventory accuracy (greater than 95%), cycle counting is one means of achieving and sustaining high degrees of accuracy. There are specific procedures to use cycle counting to quickly identify root causes of problems in the processes that control inventories and then monitor the effectiveness of the actions to eliminate the root causes. In fact, doing conventional inventory audits without having previously made the control processes reliable is like trying to weigh dry ice – soon after balances are corrected, the bad processes wrong the balances again. The purpose of cycle counting is to verify the inventory accuracy and even though it is not an adequate procedure to be used to correct inventory errors, it is an adequate way to identify the root causes of inventory errors.

They should be employees who are counting for the sake of inventory accuracy, not verifying that the numbers that they entered are accurate. MRO costs should be negotiated annually, to keep costs down. Consolidating MRO suppliers, when possible, also makes good fiscal sense, as shaving even just a few percentage points from an MRO budget can radically improve a company’s bottom line. On the other hand, failure to properly inventory a supply chain with necessary MRO items can result in production shut-downs and slow-downs, diminished product availability, and ultimately customer attrition.

There are companies that only perform inventory counts once a year or right before a given sales season. Usually, these companies do not have many products to track. Other organizations might opt for this method because they do not have the staff to carry out frequent inventory or the tools to make physical counts simpler. The person or persons who do your cycle counting shouldn’t have a stake in inventory accuracy.

Faulty inventory projections create shortages, unsold goods and wasted warehouse space. By performing a physical inventory count a business can keep its information accurate and current. How often should a company go through the warehouse and track their products and supplies? Cycle counts can introduce inventory errors if the cycle count process is poorly executed.

Looking For Help With Inventory Counting?

In contrast, identifying root causes, agreeing on actions to eliminate them and implementing them to the point of perfecting control processes is virtually impossible with traditional inventory audit approaches. By engaging in cycle counting, a business will almost certainly experience higher levels of inventory record accuracy, which leads to higher confidence in the resulting inventory valuation. This may, in turn, lead to the elimination of physical inventory counts, since the inventory records are already so accurate that no periodic physical verification is required. If inventory no longer needs to be counted at the end of each reporting period, the result can be an accelerated closing process.

The most commonly used method is simply to start in one corner of the warehouse and progress through the various aisles and bins, so that all items are counted on a rotating basis. If the latter method is used, it may also be necessary to recount certain items more frequently, if they are critical to the production process. Cycle counting involves counting a small amount of inventory in the warehouse each day, with the intent of counting the entire inventory over a period of time. Any errors found during these small incremental counts should result in an adjustment to the inventory accounting records. Also, an investigation into the reasons for each error found should be conducted.

A cycle count is an inventory auditing procedure, which falls under inventory management, where a small subset of inventory, in a specific location, is counted on a specified day. Cycle counts contrast with traditional physical inventory in that a full physical inventory may stop operation at a facility while all items are counted at one time.