Cost of Quality

Cost of Quality methodology provides the detailed information that management needs to accurately evaluate the effectiveness of their quality systems, identify problem areas and opportunities for improvement. Cost of conformance is the total cost of ensuring that a product is of good Quality. It includes costs of quality assurance activities such as standards, training and processes; and costs of quality control activities such as reviews, audits, inspections and testing. These costs are associated with the design, implementation, and maintenance of the quality management system. They are planned and incurred before actual assembly of the product at the shop floor.

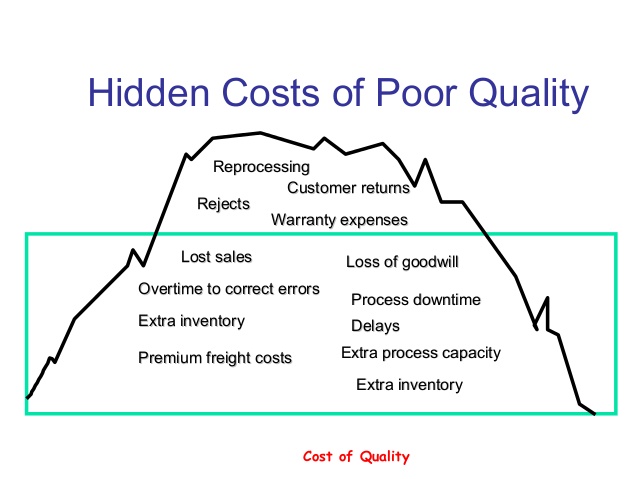

The prevention costs include specifications and inspection requirements for incoming materials, processes, and finished products, worker training and gauge calibration. The use of an MES (Manufacturing Execution System) like iBASEt’s Solumina which fully integrates an EQMS (Enterprise Quality Management System) can make a big difference to the efficiency of quality management processes. The following are some specific examples for how to reduce the cost of quality with improved quality management processes. To accurately account for the of quality costs on a small business’ budget, it is imperative to understand the hidden quality costs such as loss of sales and customer service.

It was discovered that customer part shortages originating from one work cell were resulting in warranty costs of over $400,000 in one year. A team was formed to investigate and perform Root Cause Analysis (RCA) of the shortages and a plan was developed to redesign the work cell for an estimated cost of $60,000.

The Cost of Quality equation looks simple but in reality it is more complex. There are multiple options available to the consumer for nearly every product on the market.

Cost of Quality (COQ)

Cost of poor quality (COPQ) or poor quality costs (PQC), are costs that would disappear if systems, processes, and products were perfect. Investing in the resources to identify and ultimately diagnose poor quality processes helps a business reach its strategic objectives and increase the value of the product and overall customer satisfaction. As was the case with a prevention cost, an appraisal cost is incurred in order to keep a quality problem from occurring.

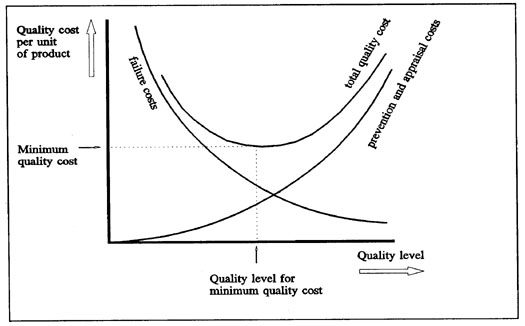

In addition to the traditional way of reducing the cost of quality by reducing the number of defects, it is possible to tackle the efficiency of the quality management system itself to further reduce cost of quality. The PAF model is a combination of ideas developed in the 1960’s by multiple quality gurus including Crosby and Juran. Their concepts emphasized that it is better to have more upfront investment utilizing preventive activities to minimize the costs caused by quality failures later in the product lifecycle. Research shows that the cost of poor quality (including rework, returns, and reduced repeat sales) can range from 15%-35% of business costs.

Within each of the four categories there are numerous possible sources of cost related to good or poor quality. Having such information allows an organization to determine the potential savings to be gained by implementing process improvements. When the customers are the ones who discover that the services or products that you’re offering have a defect, this is included on the external failure costs category. There is a natural cost tradeoff between how much an organization spends on prevention versus how much it spends on fixing failures.

With management approval, the work cell was redesigned with a revised layout, pick bins, dedicated locations for all the parts, process controls were defined and implemented and several additional improvements were made. The changes reduced tact times and the number of operators required for the process. This provided resources for the addition of quality technicians to regularly audit and maintain the process on all shifts.

Similarly, the time and people resources a company devotes to handling customer complaints reflects a cost of poor quality. External failure costs are incurred during customer use and can include defective products, warranty charges, customer complaints, replacement products, recalls and repairs. While external costs are the most apparent, these costs sometimes can be difficult to quantify. Therefore, businesses fail to include them in the overall quality costs because failures such as poor packaging and handling issues are not always reported by the customer. The discipline of quality includes the efforts directed towards the improvement of processes, being used to maintain consistency, reduce expenditures, and ensure production within the schedule baseline.

What is Cost of Quality (COQ)

Many times the customer incurs the cost of replacing a failed product, the experience may discourage the customer from purchasing from that company again, resulting in loss of sales. They include Prevention, Appraisal, Internal Failure and External Failure.

Within the first year of operation, shortages were reduced by 50% equaling a $200,000 reduction in warranty costs. The project resulted in a positive impact on the bottom line of $140,000 in the first year. Alpha Company has since implemented processes to measure and reduce scrap, improved process controls and introduced new quality metrics throughout the organization. They are now actively measuring and evaluating both the cost of good quality and poor quality. The appraisal costs are mainly related to the monitoring and measuring of the activities related to the quality of the services and products.

An organization can choose to invest in upfront quality costs to reduce or prevent failures or pay in the end when the defect is eventually discovered by the customer. Product failures can result in increased warranty costs and possibly even product recalls. In addition, there are the hard to measure costs incurred through loss of brand equity and possible decline in future sales. Cost of Quality can have an immense impact on a company’s bottom line, positive or negative. Some good examples of prevention quality costs are engineering and quality training.

- Companies pay appraisal costs as part of the quality control process to ensure that their products and services meet customer expectations and regulatory requirements.

- Within the total amount of quality cost, however, COPQ represents only a certain proportion.

- When calculating the business case for a Six Sigma project, the cost of poor quality (COPQ), which is the cost caused through producing defects, is a commonly used concept.

Appraisal costs

What is meant by cost of quality?

Cost of quality (COQ) is defined as a methodology that allows an organization to determine the extent to which its resources are used for activities that prevent poor quality, that appraise the quality of the organization’s products or services, and that result from internal and external failures.

Prevention costs include process planning, review and analysis of quality audits and training employees to prevent future failure. What is the relation between the cost of good quality and the cost of poor quality? In the example above, the Cost of Poor Quality (CoPQ) was having a major impact on the bottom line.

Appraisal in its best form is a verification that the production processes and preventive measures are working. Appraisal in its least productive form, is separating the good from the bad product, counting defects, scrapping and calculating yield. While this is a necessary part of the quality program, it is important to move towards more preventive methods to reduce the cost of failures—the cost of poor quality. Perhaps the most important quality cost investment is prevention costs. Eliminating defects before production begins reduces the costs of quality and can help companies increase profits.

James Harrington in his 1987 book Poor Quality Costs.COPQ is a refinement of the concept of quality costs. In the 1960s, IBM undertook an effort to study its own quality costs and tailored the concept for its own use. While Feigenbaum’s term “quality costs” is technically accurate, it’s easy for the uninitiated to jump to the conclusion that better quality products cost more to produce.

What are the 4 costs of quality?

The Cost of Quality can be divided into four categories. They include Prevention, Appraisal, Internal Failure and External Failure.

Costs do not result from only producing and fixing failures; a high amount of costs comes from ensuring that good products are produced. This article explains the cost of quality as a more comprehensive concept covering the cost of poor quality and the cost of good quality.

Companies pay appraisal costs as part of the quality control process to ensure that their products and services meet customer expectations and regulatory requirements. When calculating the business case for a Six Sigma project, the cost of poor quality (COPQ), which is the cost caused through producing defects, is a commonly used concept. Within the total amount of quality cost, however, COPQ represents only a certain proportion.

The top performing companies set themselves apart from the competition by listening to the voice of the customer and providing products that meet the customer’s requirements while maintaining a high level of quality and dependability. These companies measure Cost of Quality and use the information gained to their advantage. The principle of Cost of Quality is similar to a commercial that aired years ago on television that advertised oil filters. The message was that preventive maintenance of your vehicle could prevent more costly repairs down the road.

Design and production engineers work together to make sure products are manufactured to withstand normal use. Employees are trained on production processes to help eliminate manufacturing malfunctions like machine errors. These costs are incurred when you discover some defect on your services and products before you hand them to your customers. A second way to reduce the cost of quality is to make the processes for handling preventions and failures more efficient. Figure 5 shows how the cost curves would change when the focus is on improving the quality management system itself.

Cost of Quality: What is it?

The least expensive is having production workers inspect both incoming and outgoing parts to and from their workstations, which catches problems faster than other types of inspection. Other appraisal costs include the destruction of goods as part of the testing process, the depreciation of test equipment, and supervision of the testing staff. It is imperative for small businesses to understand the hidden quality costs such as loss of sales and customer service.

Many businesses include warranties in their quality costs, but they often underestimate the full financial impact if the product fails after the warranty expires. Even though the customer incurs the cost of replacing the failed product, the experience may discourage the customer from purchasing from that company again, resulting in loss of sales.

In short, any cost that would not have been expended if quality were perfect contributes to the cost of quality. Alpha Company once measured Cost of Quality as the amount of warranty cost versus total sales.

Cost of Quality resources

Through an investment in the Cost of Good Quality (CoGQ), Alpha Company achieved a significant reduction in the Cost of Quality. There are opportunities for improvement in processes at most organizations. It has been estimated that the Cost of Quality usually amounts to between 15-40% of business costs. The goal of implementing Cost of Quality methodology is to maximize product quality while minimizing cost.