Accounting For Actual And Applied Overhead

Note that the manufacturing overhead account has a debit balance when overhead is underapplied because fewer costs were applied to jobs than were actually incurred. Other examples of actual manufacturing overhead costs include factory utilities, machine maintenance, and factory supervisor salaries.

Management can answer questions, such as “How much did direct materials cost? ” This is important information when it comes time to negotiate the sales price of a jetliner with a potential buyer like United Airlines or Southwest Airlines. When this journal entry is recorded, we also record overhead applied on the appropriate job cost sheet, just as we did with direct materials and direct labor. Figure 2.6 “Overhead Applied for Custom Furniture Company’s Job 50” shows the manufacturing overhead applied based on the six hours worked by Tim Wallace. Notice that total manufacturing costs as of May 4 for job 50 are summarized at the bottom of the job cost sheet.

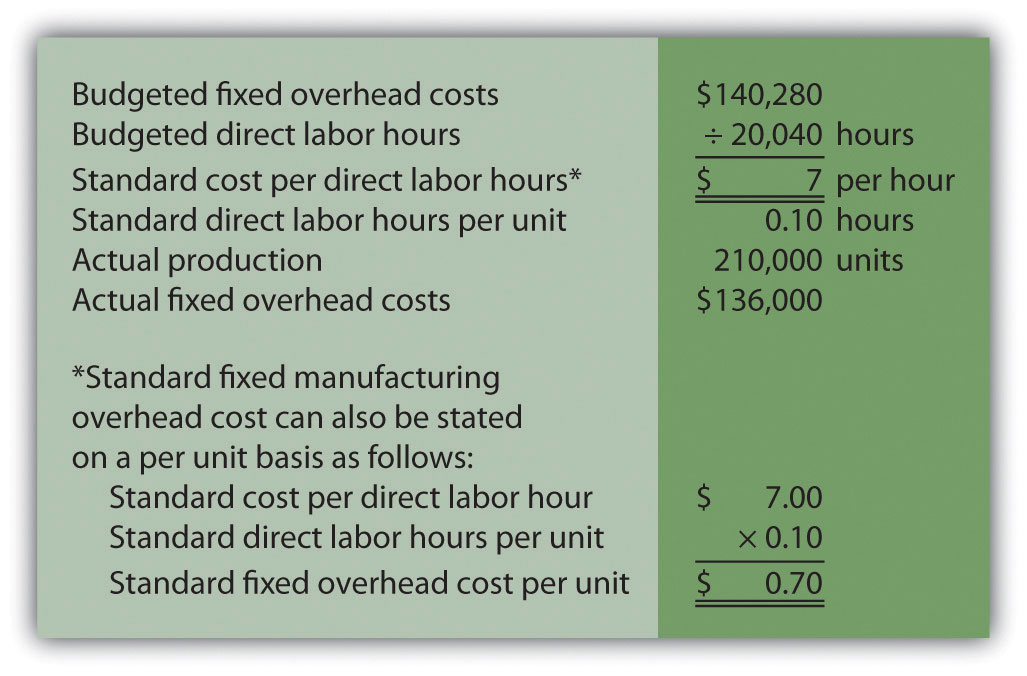

The overhead is attributed to a product or service on the basis of direct labor hours, machine hours, direct labor cost etc. The overhead absorption rate is calculated to include the overhead in the cost of production of goods and services. It’s used to define the amount to be debited for indirect labor, material and other indirect expenses for production to the work in progress.

What is included in manufacturing overhead?

Manufacturing overhead is all indirect costs incurred during the production process. This overhead is applied to the units produced within a reporting period. Examples of costs that are included in the manufacturing overhead category are: Depreciation on equipment used in the production process.

Items of the overhead

Depreciation on factory equipment, factory rent, factory insurance, factory property taxes, and factory utilities are all examples of manufacturing overhead costs. Together, the direct materials, direct labor, and manufacturing overhead are referred to as manufacturing costs. The costs of selling the product are operating expenses (period cost) and not part of manufacturing overhead costs because they are not incurred to make a product. In accounting, all costs can be described as either fixed costs or variable costs.

Note that the manufacturing overhead account has a credit balance when overhead is overapplied because more costs were applied to jobs than were actually incurred. occurs when actual overhead costs (debits) are higher than overhead applied to jobs (credits). The T-account that follows provides an example of underapplied overhead.

It includes the costs incurred in the manufacturing facilities other than the costs of direct materials and direct labor. While some of these costs are fixed such as the rent of the factory, others may vary with an increase or decrease in production. Overhead is overapplied because actual overhead costs are lower than overhead applied to jobs.

All these costs are recorded as debits in the manufacturing overhead account when incurred. Using a manufacturing overhead cost formula and calculating the total costs per unit will help you determine whether you need to adjust your selling price.

Add the direct materials costs, direct labor costs and factory overhead costs, then divide that number by the total number of units produced. Since direct materials and direct labor are usually considered to be the only costs that directly apply to a unit of production, manufacturing overhead is (by default) all of the indirect costs of a factory. Examples of product costs are direct materials, direct labor, and allocated factory overhead.

Direct labor and manufacturing overhead costs (think huge production facilities!) are also assigned to each jetliner. This careful tracking of production costs for each jetliner provides management with important cost information that is used to assess production efficiency and profitability.

Manufacturing overhead

However, overheads are still vital to business operations as they provide critical support for the business to carry out profit making activities. For example, overhead costs such as the rent for a factory allows workers to manufacture products which can then be sold for a profit. Overheads are also very important cost element along with direct materials and direct labor.

- Direct materials are those materials (including purchased parts) that are used to make a product and can be directly associated with the product.

Variable costs include direct labor, direct materials, and variable overhead. Since most of Boeing’s products are unique and costly, the company likely uses job costing to track costs associated with each product it manufactures. For example, the costly direct materials that go into each jetliner produced are tracked using a job cost sheet.

Chan Company estimates that annual manufacturing overhead costs will be $500,000. Chan allocates overhead to jobs based on machine hours, and it expects that 100,000 machine hours will be required for the year. To calculate manufacturing overhead, you need to add all the indirect factory-related expenses incurred in manufacturing a product. This includes the costs of indirect materials, indirect labor, machine repairs, depreciation, factory supplies, insurance, electricity and more.

You saw an example of this earlier when $180 in overhead was applied to job 50 for Custom Furniture Company. In business, overhead or overhead expense refers to an ongoing expense of operating a business. Overheads are the expenditure which cannot be conveniently traced to or identified with any particular cost unit, unlike operating expenses such as raw material and labor. Therefore, overheads cannot be immediately associated with the products or services being offered, thus do not directly generate profits.

All costs that do not fluctuate directly with production volume are fixed costs. Fixed costs include various indirect costs and fixed manufacturing overhead costs.

Identify Factory Overhead Costs

Manufacturing overhead – also called indirect costs – are any costs that a factory incurs other than direct materials and direct labor needed to manufacture goods, notes “Accounting 2,” a reference guide. In cost accounting, manufacturing overhead is applied to the units produced within a reporting period, according to Accounting Tools, a website that offers professional accounting courses and materials. Second, the manufacturing overhead account tracks overhead costs applied to jobs. The overhead costs applied to jobs using a predetermined overhead rate are recorded as credits in the manufacturing overhead account.

occurs when actual overhead costs (debits) are lower than overhead applied to jobs (credits). The T-account that follows provides an example of overapplied overhead.

Make a comprehensive list of indirect business expenses including items like rent, taxes, utilities, office equipment, factory maintenance etc. Direct expenses related to the production of goods and services, such as labor and raw materials, are not included in overhead costs. The allocation base is the basis on which a business assigns overhead costs to products. The commonly used allocation bases in manufacturing are direct machine hours and direct labor hours. Manufacturing overhead (also known as factory overhead, factory burden, production overhead) involves a company’s manufacturing operations.

Definition of Manufacturing Overhead

Variable costs are inventoriable costs – they are allocated to units of production and recorded in inventory accounts, such as cost of goods sold. Fixed costs, on the other hand, are all costs that are not inventoriable costs.

Direct materials are those materials (including purchased parts) that are used to make a product and can be directly associated with the product. Some materials used in making a product have a minimal cost, such as screws, nails, and glue, or do not become part of the final product, such as lubricants for machines and tape used when painting. Such materials are called indirect materials and are accounted for as manufacturing overhead. Manufacturing overhead costs include indirect materials, indirect labor, and all other manufacturing costs.